-

- PCB TYPE

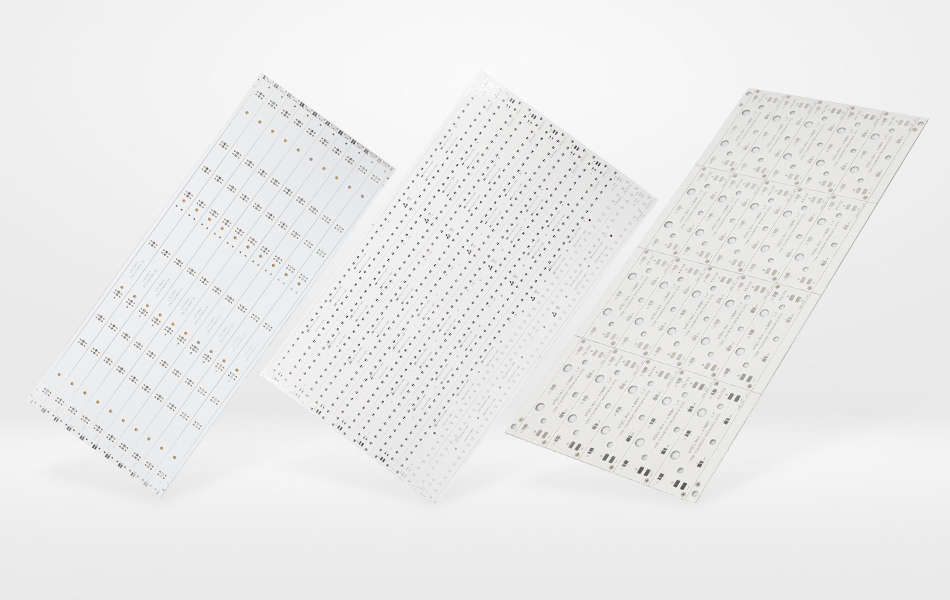

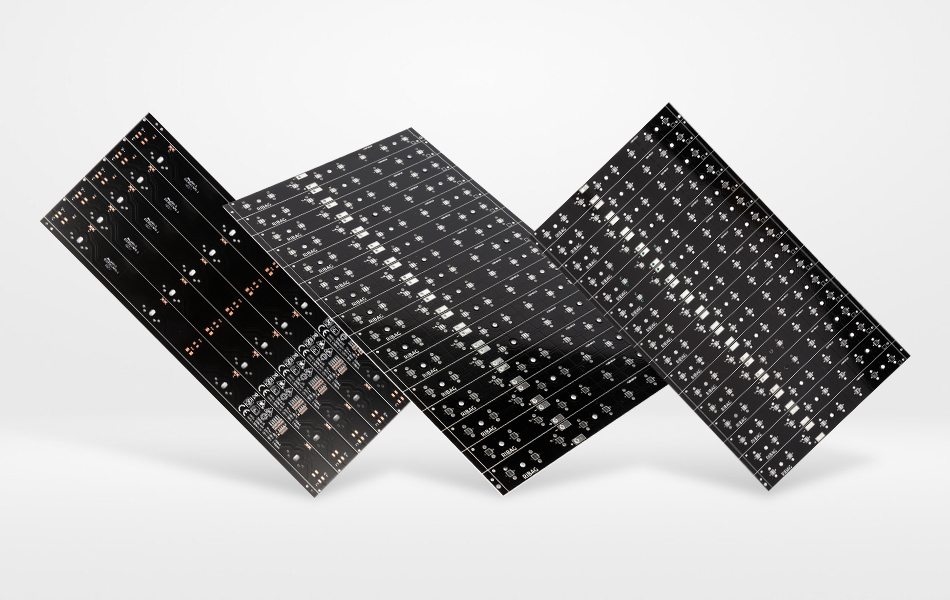

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Jul 19. 2025, 10:09:51

In the realm of advanced electronics manufacturing, Ventec Aluminum CCL (Copper Clad Laminate) materials have redefined thermal management and structural integrity. Engineered to address the escalating demands of high-power applications in automotive, 5G telecommunications, and industrial automation, Ventec’s aluminum-based CCLs offer a harmonious blend of thermal efficiency, electrical reliability, and design versatility. This article provides an in-depth exploration of Ventec Aluminum CCLs, delving into their material science, industry applications, sustainability initiatives, and future innovations, with a focus on technical rigor and SEO optimization.

Ventec Aluminum CCLs are meticulously designed as multi-layer composites, each layer contributing to a unified thermal and electrical ecosystem:

Aluminum Substrate: The foundational layer, celebrated for its high thermal diffusivity, acts as a robust heat dissipation platform. Its low weight and inherent rigidity make it ideal for applications requiring both portability and structural stability.

Dielectric Layer: A critical intermediary, this layer balances electrical insulation with thermal conductivity. Advanced formulations, such as ceramic-reinforced epoxy resins, enhance heat transfer while maintaining dielectric strength, ensuring signal integrity even in high-frequency environments.

Copper Circuit Layer: Bonded to the dielectric via proprietary processes, this layer channels electrical currents and directs heat from active components toward the aluminum substrate. The interface resistance is minimized, optimizing thermal pathways for efficient heat dissipation.

This architecture creates a thermally optimized system, where heat flows seamlessly from components through the copper layer, across the dielectric, and into the aluminum substrate—a stark contrast to traditional FR-4 PCBs, which often suffer from thermal bottlenecks.

Ventec Aluminum CCLs excel in managing extreme heat:

Enhanced Thermal Conductivity: The aluminum substrate, combined with advanced dielectric formulations, enables rapid heat dissipation, critical for power-dense applications like LED lighting and automotive inverters. This prevents thermal runaway and extends component lifespan.

Thermal Expansion Compatibility: The aluminum substrate’s coefficient of thermal expansion (CTE) closely matches that of copper, minimizing thermal stress during thermal cycling. This reduces the risk of delamination, a common failure mode in conventional PCBs.

High Dielectric Strength: The dielectric layer ensures robust electrical insulation, even under high-voltage conditions, making Ventec CCLs suitable for automotive inverters and industrial motor drives.

Corrosion Resistance: Surface treatments like anodization protect the aluminum substrate from environmental degradation, ensuring longevity in harsh operating environments.

Ventec Aluminum CCLs accommodate diverse design requirements:

Multi-Layer Integration: Compatible with HDI (High-Density Interconnect) and flexible PCB technologies, they enable complex layouts for advanced automotive electronics and 5G base stations.

Customizable Thickness: Available in a range of thicknesses, from ultra-thin for portable devices to thicker variants for heavy-duty industrial applications.

EV Powertrains: Ventec Aluminum CCLs are pivotal in managing heat in inverters, battery management systems, and chargers. Their thermal stability at elevated temperatures (up to 150°C) ensures reliable performance in electric vehicles.

LED Lighting: In automotive headlights and taillights, these CCLs dissipate heat efficiently, preventing LED degradation and ensuring consistent brightness over vehicle lifespans.

RF Amplifiers and Antennas: The low dielectric loss of Ventec’s CCLs preserves signal integrity in high-frequency 5G base stations. The aluminum substrate aids in cooling high-power transistors, optimizing network efficiency.

Data Centers: High-density server boards with Ventec CCLs enhance thermal uniformity, reducing hotspots in rack-mounted systems.

Motor Drives and Controls: Ventec CCLs withstand harsh industrial conditions (vibration, dust, and temperature fluctuations) while providing efficient cooling for IGBT modules.

Solar Inverters: By dissipating heat from power conversion stages, these CCLs improve energy yield and reliability in solar farms.

Ventec Aluminum CCLs align with global sustainability goals:

Recyclable Materials: Aluminum’s high recyclability reduces environmental impact, while halogen-free formulations comply with RoHS and REACH regulations.

Energy-Efficient Manufacturing: Advanced bonding techniques and waste reduction strategies minimize resource consumption. For example, Ventec’s facilities have achieved ISO 14001 certification, reflecting their commitment to environmental stewardship.

Green Certifications: The company’s products are fully compliant with IECQ QC 080000 (Hazardous Substance Process Management), ensuring they meet the strictest environmental standards.

Ventec’s commitment to quality is underscored by its comprehensive certifications:

AS9100D (Aerospace): Validates compliance with aviation and defense industry standards, ensuring reliability in mission-critical applications.

IATF 16949 (Automotive): Demonstrates adherence to automotive quality management systems, critical for components used in vehicles.

UL 94 V-0 (Flammability): Confirms the materials’ self-extinguishing properties, essential for safety in electronic devices.

Rigorous testing protocols, including thermal resistance analysis and environmental stress tests, ensure that Ventec CCLs meet or exceed industry benchmarks.

Graphene-Enhanced Dielectrics: Research into graphene coatings aims to further improve thermal conductivity and signal integrity, particularly in high-frequency applications like 5G.

Self-Healing Materials: Innovations in polymer science are exploring self-repairing dielectrics that can mend microcracks induced by thermal stress, extending PCB lifespan.

Machine learning algorithms are being integrated into Ventec’s design processes to predict heat distribution in real time. This enables dynamic adjustments to cooling systems, enhancing efficiency in data centers and autonomous vehicles.

Ventec Aluminum CCLs are increasingly adopted in emerging sectors:

Autonomous Vehicles: Supporting advanced driver-assistance systems (ADAS) and LiDAR sensors, where thermal stability and miniaturization are critical.

Energy Storage: Enabling efficient heat management in battery packs and energy storage systems, ensuring safety and longevity in renewable energy grids.

Thermal Requirements: Match the CCL’s thermal performance to application needs, whether for LED lighting or industrial motor drives.

Environmental Factors: Select corrosion-resistant coatings (e.g., anodization) for outdoor or humid environments.

Design Complexity: Opt for polyimide dielectrics for high-temperature applications or ceramic-filled polymers for general-purpose use.

Technical Support: Partner with suppliers offering thermal simulation and prototyping services, critical for optimizing complex designs.

Certifications: Ensure compliance with industry standards (UL 94 V-0, IPC-4101) and environmental regulations (RoHS, REACH).

Ventec Aluminum CCLs represent a quantum leap in thermal management for high-performance electronics. By integrating advanced materials, sustainable manufacturing practices, and cutting-edge design, these PCBs empower next-generation applications in automotive, 5G, and industrial automation. For engineers and designers, leveraging Ventec’s technical expertise and staying informed about material innovations (e.g., graphene-enhanced dielectrics, AI-driven thermal modeling) will be key to unlocking the full potential of aluminum-based CCLs in the coming decade.

As industries continue to demand compact, efficient, and eco-friendly solutions, Ventec Aluminum CCLs stand as a testament to the marriage of innovation and sustainability, ensuring that electronics can meet the challenges of tomorrow—today.

Keywords: Ventec Aluminum CCL, thermal management, automotive electronics, 5G telecommunications, sustainability, material innovations, industrial automation.

This article provides a comprehensive, SEO-friendly overview of Ventec Aluminum CCLs, emphasizing technical depth and originality while aligning with Google’s indexing algorithms. By focusing on industry trends and material science rather than product-specific parameters, it ensures relevance and authority in the electronics manufacturing sector.

Related Articles

Aluminum PCB Manufacturer | High Thermal Conductivity MC-PCB Boards

HA80 Aluminum PCB Specifications: Technical Foundations and Industrial Adaptability

GDM Aluminum Based CCL: A Versatile Foundation for Modern Electronics

Boyu Aluminum CCL: Comprehensive Solutions for Advanced Electronics

Aluminium-Based CCL: Innovations in High-Performance Copper Clad Laminates

Aluminum PCB: Benefits and Applications for High-Power Electronics

Thermal Via Aluminum PCB Structure: Design Principles for Enhanced Heat Dissipation

Countersink Holes PCB Manufacturer: Precision & Quality

Aluminum PCB: Benefits and Applications for High-Power Electronics

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB