-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

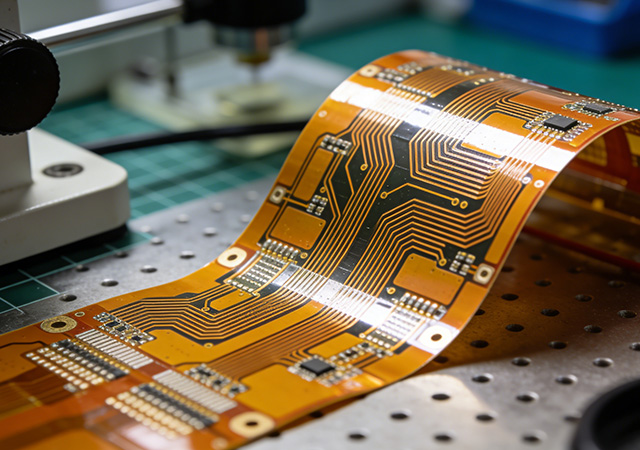

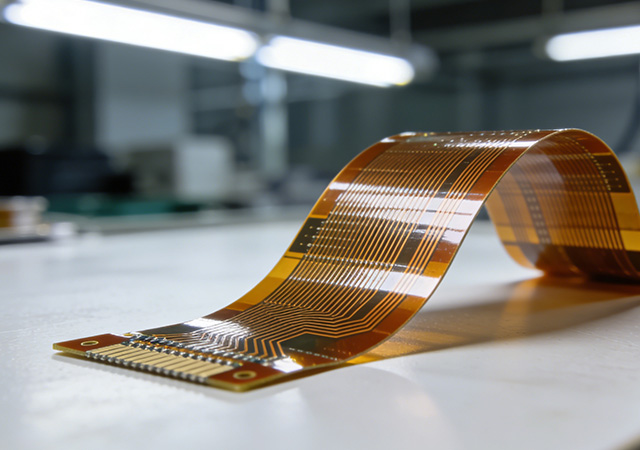

In the fast-evolving global electronics industry, the performance and versatility of flexible printed circuits (FPCs) have become decisive factors in product innovation. A professional FPC manufacturer distinguishes itself through cutting-edge material innovation and tailored engineering capabilities, going beyond standardized production to deliver high-performance, application-specific FPC solutions. Unlike generic component suppliers, leading FPC manufacturers prioritize R&D in advanced materials and precision engineering, enabling them to address the unique challenges of emerging electronic applications—from wearable devices to industrial IoT sensors. For electronics brands striving to gain a competitive edge, partnering with an FPC manufacturer that excels in material innovation and customization is essential to unlocking product potential and meeting evolving market demands.

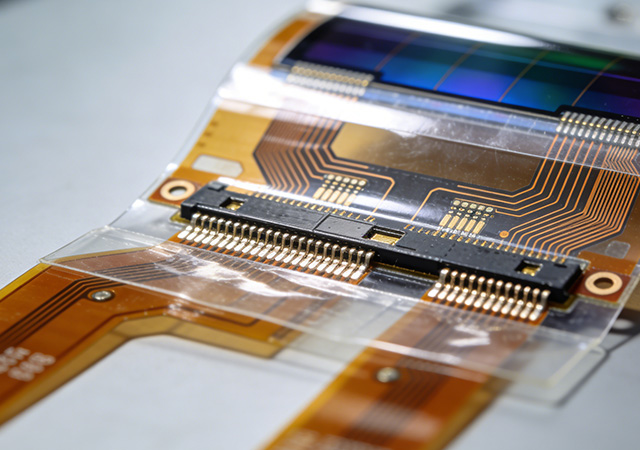

As display technologies evolve at a rapid pace—spanning OLED, LCD, mini/micro-LED, and emerging transparent displays—professional Display FPC manufacturers have become the backbone of the global display industry. Specializing in flexible printed circuits (FPCs) tailored to the diverse operational and design demands of display products, these manufacturers go beyond generic component supply: they adapt to the unique technical characteristics of different display types, balancing signal integrity, structural compatibility, and long-term reliability. Unlike niche FPC suppliers focused on single display segments, a comprehensive Display FPC manufacturer caters to consumer electronics, commercial signage, automotive displays, and industrial monitors, enabling display brands to bring innovative, high-performance products to market. For enterprises aiming to excel in the competitive display ecosystem, partnering with a versatile Display FPC manufacturer is a strategic imperative.

As flexible display technologies—represented by foldable OLED, rollable AMOLED, and bendable micro-LED—redefine the form factors of electronic devices, a professional Flexible Display FPC Supplier has become an indispensable cornerstone of the display innovation ecosystem. Specializing in flexible printed circuits (FPCs) engineered for the dynamic operating demands of flexible displays, these suppliers bridge the gap between bold morphological designs (fold, roll, bend) and consistent, long-term performance. Unlike generic FPC suppliers, a Flexible Display FPC Supplier focuses on bend-resistant material integration, dynamic circuit optimization, and multi-form factor adaptability, ensuring FPCs can withstand millions of bending cycles while maintaining stable signal transmission. For display brands and device manufacturers aiming to lead in the flexible display market, partnering with a reputable Flexible Display FPC Supplier is critical to translating innovative design concepts into m

As display technologies evolve toward ultra-high resolution (UHD, 8K, and beyond), flexible OLED, and mini/micro-LED solutions, a professional High Resolution Display FPC Maker has become a critical enabler of pixel-perfect visual experiences. Specializing in flexible printed circuits (FPCs) engineered for the unique demands of high-resolution displays, these makers bridge the gap between dense pixel arrays, high-frequency signal transmission, and the flexible form factors of modern screens. Unlike generic FPC manufacturers, a High Resolution Display FPC Maker focuses on precision circuit design, low-loss material integration, and signal integrity optimization—ensuring FPCs can support the massive data throughput required for high-res visuals without compromising display clarity or response speed. For display brands aiming to lead in premium markets (e.g., high-end smartphones, 8K TVs, AR/VR headsets), partnering with a reputable High Resolution Display FPC Maker is essential to delive

In the era of Industry 4.0 and intelligent manufacturing, a professional FPC manufacturer is no longer confined to traditional component production but evolves into a digital-driven partner that empowers the entire electronics industry’s smart upgrading. By integrating advanced digital technologies into every link of FPC design, production, and service, these manufacturers break through the limitations of traditional manufacturing, achieving higher efficiency, better quality, and deeper collaboration with customers. Unlike manufacturers stuck in conventional processes, a forward-looking FPC manufacturer focuses on digital transformation and smart ecosystem building, enabling seamless connection with customers’ intelligent product development and production systems. For electronics enterprises pursuing high efficiency, innovation, and intelligent upgrading, partnering with a digitally transformed FPC manufacturer is a crucial strategic choice to gain a competitive edge in the global mar

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB