-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

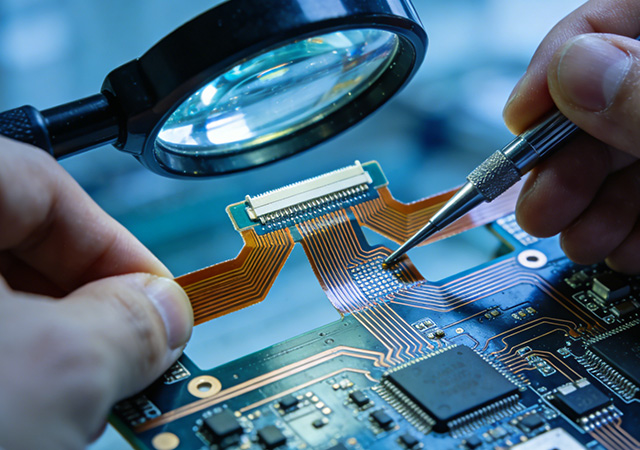

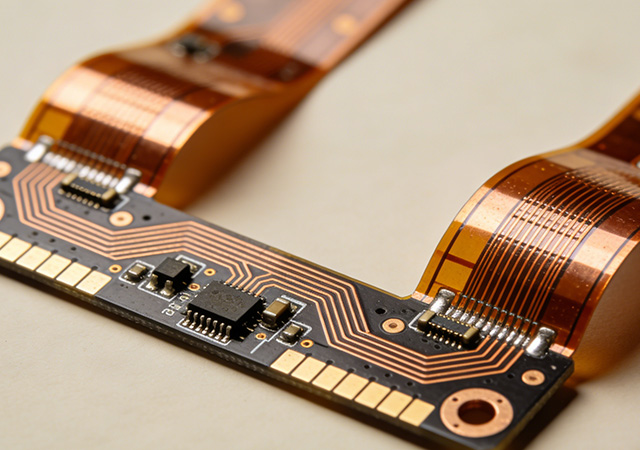

In the fast-paced electronics industry, where product lifecycles are shrinking and market competition is intensifying, the ability to bring new products to market quickly has become a decisive competitive advantage. For businesses developing flexible electronic devices, Quick Turn FPCB Assembly Service emerges as a critical enabler, bridging the gap between design validation and mass production with efficient, timely assembly solutions. This specialized service not only shortens lead times but also ensures that flexible printed circuit boards (FPCBs) meet the rigorous performance requirements of diverse applications, from consumer gadgets to medical devices and automotive electronics.

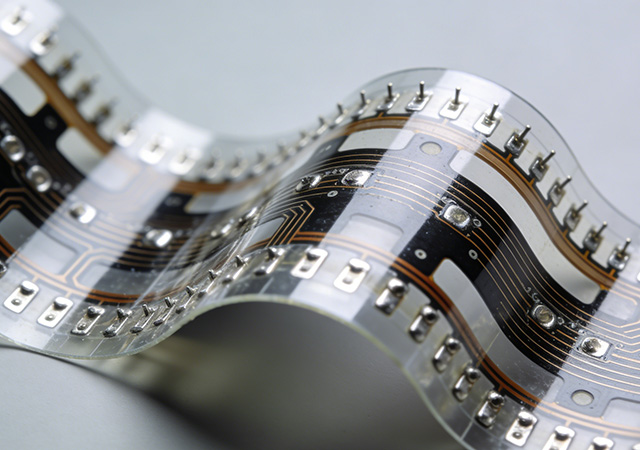

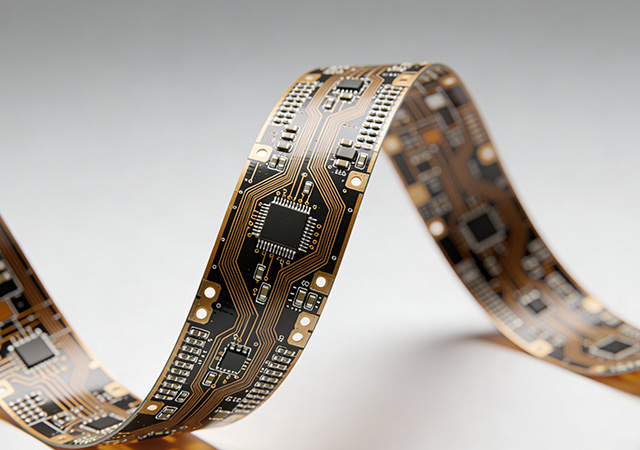

In the fast-evolving landscape of electronic technology, the demand for components that blend performance, adaptability, and compactness has reached new heights. Among these innovative components, flexible PCB (printed circuit board) stands out as a game-changer, redefining the possibilities of device design and functionality across countless industries. Unlike traditional rigid circuit boards, flexible PCB offers unique bendability, lightweight properties, and space-saving advantages, making it an indispensable choice for cutting-edge electronic products. As consumers and industries alike pursue smarter, smaller, and more durable devices, the role of flexible PCB in powering modern electronics continues to grow in significance.

The global electronics industry is experiencing a paradigm shift toward interconnected, adaptable, and eco-conscious systems, and flexible PCB has emerged as a cornerstone technology enabling this transformation. Beyond its traditional role in consumer electronics, flexible PCB now serves as a critical enabler for emerging ecosystems including smart textiles, batteryless IoT devices, and extreme-environment electronics. By virtue of its inherent mechanical compliance, lightweight design, and compatibility with multifunctional integration, flexible PCB is breaking down the barriers between electronic components and everyday objects. For manufacturers and innovators, leveraging the latest advancements in flexible PCB technology is essential to unlocking new product possibilities and capturing opportunities in high-growth emerging markets.

In the era of precision electronics, the quality of flexible PCB boards directly determines the performance, lifespan, and safety of end products. Quality Flexible PCB Board, distinguished by rigorous quality control throughout the entire production lifecycle, has become a core requirement for manufacturers across consumer electronics, medical devices, and automotive industries. Unlike low-cost flexible PCBs that prioritize cost over performance, Quality Flexible PCB Board integrates premium materials, precision manufacturing, and comprehensive quality verification to ensure consistent electrical and mechanical performance. For electronics brands, adopting Quality Flexible PCB Board is not only a means to reduce product failure rates and maintenance costs but also a key strategy to enhance brand reputation and gain a competitive edge in global markets.

In mission-critical sectors such as aerospace, industrial control, and new energy vehicles, the performance stability of electronic components directly determines operational safety and efficiency. High Reliability Flex PCB Board emerges as a core solution, engineered to withstand extreme environmental stresses while maintaining consistent electrical and mechanical performance. Unlike standard flexible PCBs designed for consumer electronics, this specialized circuit board integrates robust structural designs, high-performance materials, and rigorous quality control processes. For manufacturers operating in high-stakes industries, adopting High Reliability Flex PCB Board is not only a technical necessity but also a strategic guarantee to minimize downtime, reduce maintenance costs, and ensure compliance with industry-specific safety standards.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB