-

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

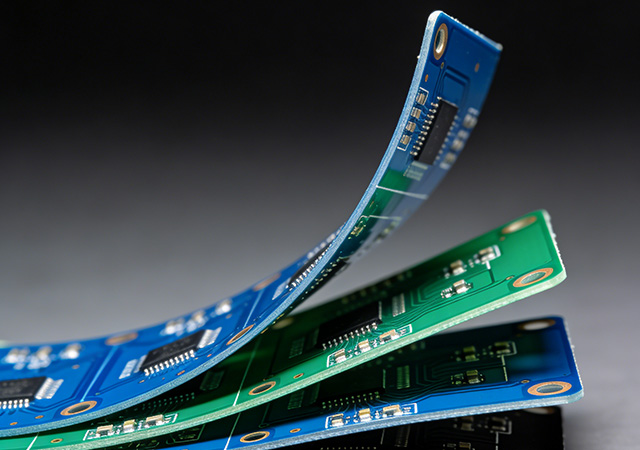

As the global electronics industry marches toward miniaturization, intelligence, and eco-friendliness, flexible PCB has evolved from a supporting component to a core enabler of technological innovation. Beyond its traditional advantages of thinness, light weight, and bendability, modern flexible PCB is driving breakthroughs in material science, sustainable manufacturing, and niche high-end applications. Unlike conventional rigid PCBs and early flexible circuits, today’s advanced flexible PCB integrates novel materials such as liquid metals and recyclable polymers, addressing critical challenges in stretchability, durability, and environmental impact. For electronics manufacturers and designers, understanding these emerging trends in flexible PCB is essential to unlocking new product possibilities and gaining a competitive edge in fast-evolving markets.

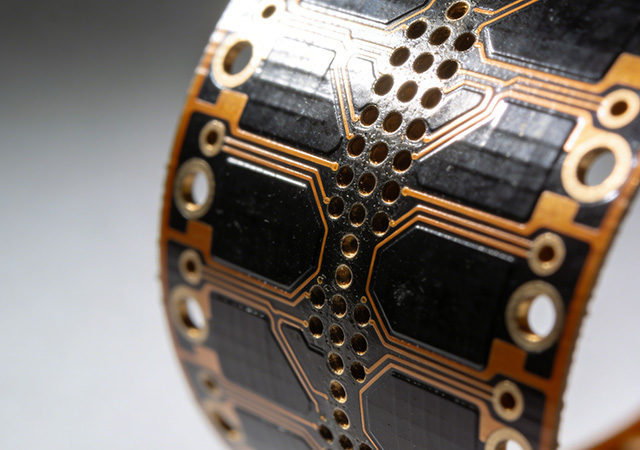

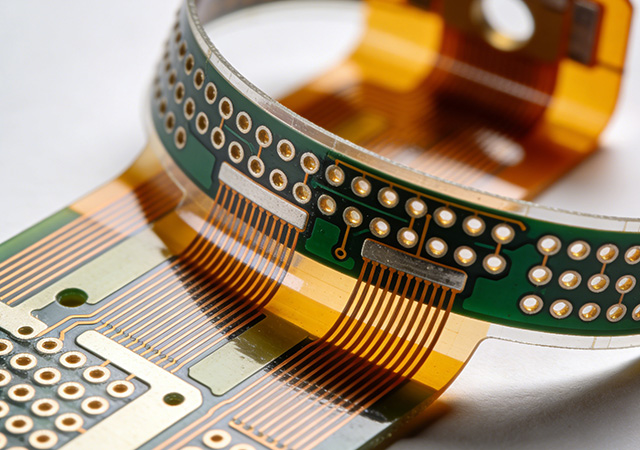

As the electronics industry evolves toward miniaturization, high-frequency operation, and multi-functional integration, the demand for flexible PCBs capable of supporting dense interconnections and reliable signal transmission has never been higher. Blind and Buried Vias Flexible PCB emerges as a pivotal solution, integrating blind vias (connecting surface and inner layers) and buried vias (linking inner layers exclusively) into flexible substrates to overcome the limitations of traditional through-hole designs. Unlike standard flexible PCBs, this advanced technology achieves superior space utilization, minimized signal loss, and enhanced mechanical flexibility—critical for powering 5G communication, autonomous driving, and wearable smart devices. For electronics manufacturers pursuing innovation in high-performance, compact products, Blind and Buried Vias Flexible PCB has become an indispensable core component.

In the era of precision medicine and intelligent healthcare, medical electronic devices are evolving toward miniaturization, invasiveness, and real-time data monitoring. Medical Grade Vias Flexible PCB, a specialized circuit solution tailored for healthcare applications, has emerged as a critical component by integrating biocompatible materials, reliable via structures, and strict compliance with medical industry standards. Unlike conventional flexible PCBs, it must meet rigorous requirements for biocompatibility, sterilization resistance, and signal integrity to ensure safe and stable operation in complex medical environments—from human body implantation to high-precision diagnostic equipment. For medical device manufacturers, adopting Medical Grade Vias Flexible PCB is essential to advancing diagnostic accuracy, treatment efficacy, and patient safety.

As electronic devices pursue extreme miniaturization, high functionality, and reliable flexibility, HDI Blind/Buried Vias Flexible PCB has emerged as a critical enabling technology. By integrating high-density interconnect (HDI) design with blind and buried via structures on flexible substrates, this specialized circuit solution breaks through the spatial limitations of traditional flexible PCBs, achieving denser线路布局 and more efficient layer-to-layer interconnection. Unlike standard flexible PCBs that rely on through-holes, HDI Blind/Buried Vias Flexible PCB minimizes substrate damage, optimizes signal transmission, and supports the compact design of high-end electronic products. For industries such as foldable electronics, automotive intelligence, and precision medical devices, this technology has become a key driver of product innovation and performance upgrading.

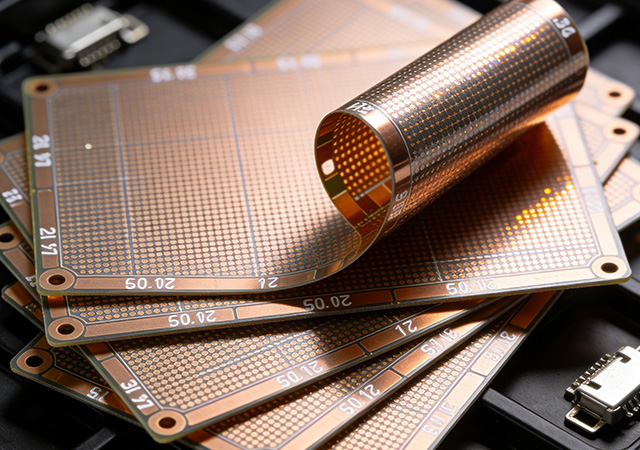

As electronic devices evolve toward miniaturization, flexibility, and multi-functionality, Flexible PCB (FPC) has become a core component supporting industrial upgrading in consumer electronics, automotive electronics, and medical devices. The traditional manufacturing model of FPC, however, has long been plagued by challenges such as low production efficiency, high defect rates, and difficulty in balancing mass production and customization. In recent years, advanced manufacturing technologies represented by laser welding and roll-to-roll production have brought revolutionary changes to the FPC industry. These innovations not only solve the core pain points of traditional manufacturing but also enable FPC to meet the diverse needs of emerging applications. For electronics manufacturers, understanding the advanced manufacturing trends of Flexible PCB is crucial to improving product competitiveness and seizing market opportunities.

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB