-

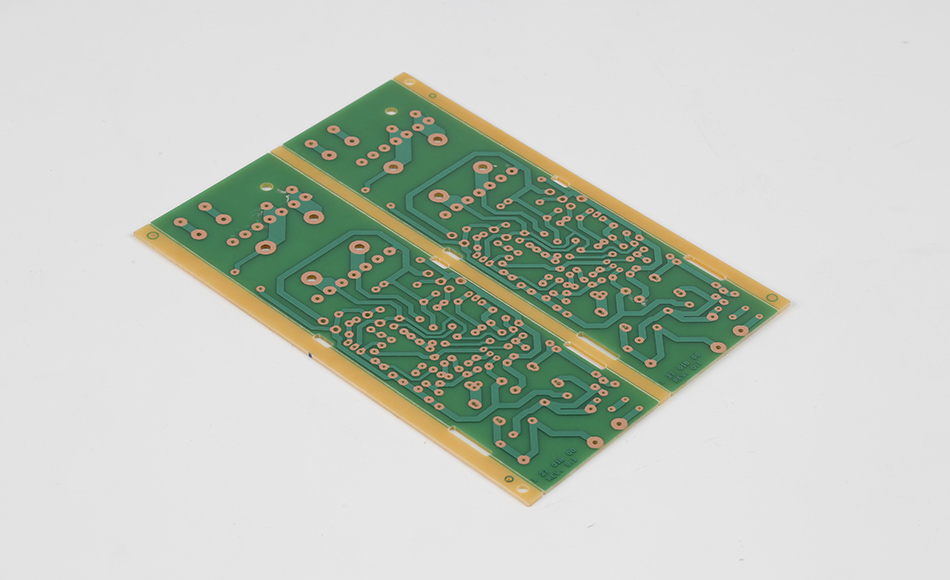

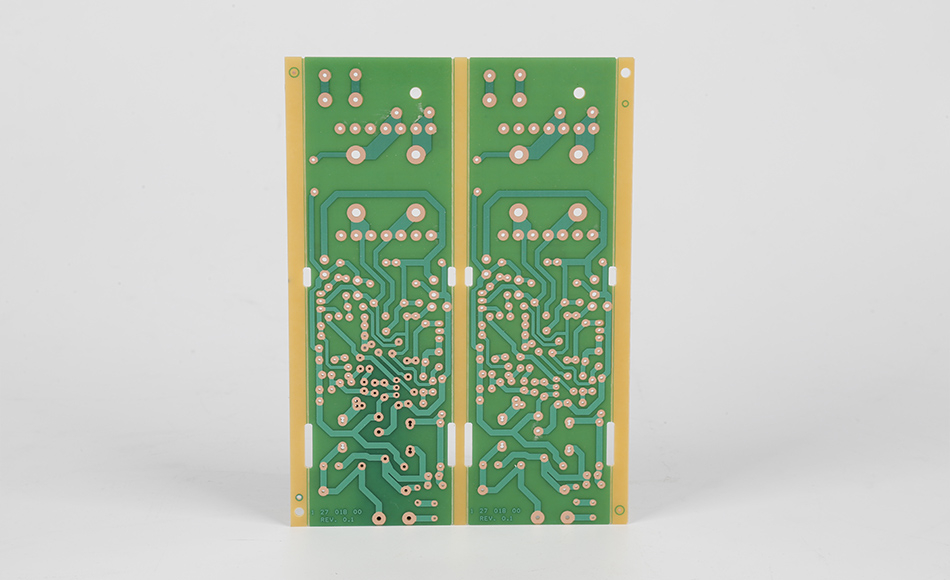

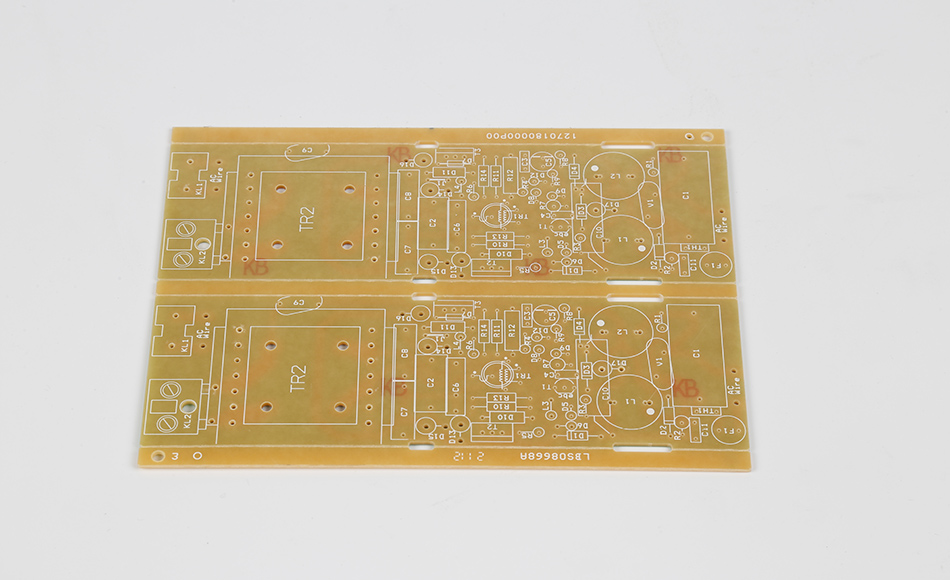

- PCB TYPE

- PRINTED CIRCUIT BOARD PROTOTYPE ALUMINUM PRINTED CIRCUIT BOARD R&F PCB FPC HIGH FREQUENCY PCB HIGH-TG PCB HEAVY COPPER PCB HDI PCB PCB FOR LIGHTING METAL CORE PCB

time:Aug 29. 2025, 20:20:33

ST210G CEM3 Thermal Performance is critical for high-power electronics (industrial power supplies, automotive BMS) where heat dissipation impacts reliability, lifespan, and safety. Unlike standard CEM3 (prioritizing insulation over thermal efficiency), ST210G balances thermal conductivity, stability, and mechanical strength—solving heat-related issues in 70°C–125°C applications.

Per the Arrhenius equation, 10°C higher operating temperature cuts component lifespan by 50%. Standard CEM3 (<0.3 W/m·K conductivity) traps heat, causing hot spots. ST210G enhances thermal transfer while retaining CEM3’s insulation and cost-effectiveness for mid-tier electronics.

This article explores ST210G’s core thermal traits, real-world applications, PCB design optimizations, and future trends—supporting engineers building durable high-power systems.

ST210G’s thermal traits make it versatile across high-power sectors. Below are key use cases solving industry-specific heat challenges.

Industrial power supplies (500W–1kW AC-DC converters) generate heat from rectifiers, transformers, and semiconductors—housed in sealed, space-constrained enclosures. ST210G addresses this:

Heat Spreading: High in-plane conductivity spreads heat from 100W MOSFETs across the PCB, lowering local temperatures by 15–20°C vs. standard CEM3. Eliminates large heat sinks, saving enclosure space.

Stability at Full Load: At 100% load (max heat), ST210G retains rigidity and insulation. An industrial power supply manufacturer cut field failures 40% (8% to 4.8% annually) with ST210G.

Passive Cooling Compatibility: Pairing ST210G with 2mm thermal vias in a 750W supply reduced MOSFET temperatures by 22°C, extending component lifespan from 3 to 7 years.

Case Study: A global industrial firm switched to ST210G for 1kW power supply PCBs. Thermal imaging showed hot spots dropped from 135°C to 112°C (below 120°C component limits). Heat sink size shrank 30%, cutting power supply weight by 25% and costs by 18%.

EV BMS modules monitor battery voltage/temperature, operating in 60°C–105°C battery packs with limited cooling. ST210G is critical:

Long-Term Thermal Stability: EV BMS need 10+ year lifespans. ST210G’s resistance to thermal degradation ensures performance; standard CEM3 BMS fail after 5–6 years.

CTE-Matched Solder Joints: ST210G’s CTE aligns with lithium-ion battery connectors, cutting solder joint failures by 50% vs. standard CEM3 in 1,000 charge-discharge cycles.

Moisture Resistance: Battery pack condensation risks short circuits—ST210G’s low absorption prevents insulation degradation. An EV maker reported zero moisture-related BMS failures in 10,000 ST210G-equipped vehicles (vs. 12 with standard CEM3).

Result: A leading EV Tier 1 supplier used ST210G for BMS PCBs. Testing showed ±0.5°C temperature accuracy at 105°C (meeting ±1°C requirements) and 2,000 charge-discharge cycles with no degradation—meeting the 10-year warranty target.

Cordless power tools (20V drills, grinders) experience extreme thermal shock: 90°C during use, ambient when off. ST210G supports this:

Shock Durability: ST210G survived 5,000 on/off cycles (30s on/off) with no damage; standard CEM3 cracked at 2,800 cycles.

Motor Driver Heat Dissipation: 30–50W motor drivers transfer heat to tool housings via ST210G, lowering temperatures by 18°C vs. standard CEM3. Extends driver lifespan from 1,000 to 2,500 hours.

Mechanical Flexibility: Unlike rigid metal-core PCBs, ST210G retains CEM3’s flexibility, surviving construction site drops. Field studies showed 35% fewer PCB failures vs. metal-core designs.

Case Study: A power tool maker adopted ST210G for 20V angle grinder PCBs. Thermal shutdowns fell 60%, tool lifespan doubled, and warranty claims dropped 28%—saving $1.2 million annually.

ST210G’s baseline thermal performance improves with targeted PCB design. Below are actionable strategies for engineers.

Thermal vias move heat from top (high-power components) to bottom (cooling solutions). Maximize ST210G’s through-plane conductivity:

Size and Density: Use 0.3–0.5mm vias (compatible with ST210G’s strength) spaced 1–2mm under high-power parts. A 4x4 array of 0.4mm vias under a 50W voltage regulator cuts temperature by 25°C vs. a 2x2 array.

Filling: Fill vias with conductive epoxy/solder (not empty). Increases through-plane transfer by 40%—critical for sealed enclosures with no airflow.

Placement: Position vias within 0.5mm of component pads (minimizing heat distance). Avoid component leads; use thermal pad areas to prevent solder issues.

Example: A 750W power supply designer used a 6x6 array of 0.4mm filled vias under a 100W MOSFET. Thermal imaging showed temperatures drop from 128°C to 101°C (below 125°C limits).

ST210G’s high in-plane conductivity works best with heat-spreading layouts:

Copper Planes: Use 2oz/4oz solid copper planes on top/bottom layers. Copper (401 W/m·K) amplifies ST210G’s heat spread. A 4oz plane in a 500W supply reduced max PCB temperature by 12°C vs. 1oz.

Component Spacing: Group high-power parts (MOSFETs, rectifiers) near copper planes/heat sinks. Spread them 5–10mm apart to avoid overlapping hot spots. A BMS designer spaced three 30W drivers 8mm apart, cutting max temperature by 10°C vs. clustering.

Power Trace Width: Use 2–4mm wide traces for high-current paths (BMS battery connections). Reduces resistive heating and adds heat-spreading paths. A 3mm trace in a 20A BMS generated 30% less heat vs. 1mm.

ST210G performs best with complementary cooling. Adapt strategies to environments:

Passive Cooling (Sealed Enclosures): Attach ST210G PCBs to aluminum heat spreaders with thermal adhesive (fills air gaps). Cut PCB temperature by 18°C in a sealed industrial supply.

Active Cooling (Airflow Available): Direct fans over copper planes/high-power components. Use temperature-controlled fan speeds (via sensors) to balance cooling/efficiency. Reduced motor driver temperature by 22°C in a power tool.

Heat Sinks: Mount 10–15mm low-profile heat sinks to high-power parts with thermal grease. ST210G’s flat surface ensures good contact (thinner grease = better transfer). A 12mm sink on a 75W BMS driver cut temperature by 28°C.

As high-power electronics shrink and electrification expands (EVs, renewables), ST210G evolves to meet new thermal demands. Below are key trends:

Next-gen electronics (2kW EV chargers, 1.5kW solar inverters) need better heat dissipation. Manufacturers optimize ST210G’s fillers:

Nanoparticle Fillers: Boron nitride nanoparticles boost in-plane conductivity to ~1.2 W/m·K (50% higher than current ST210G). Early prototypes cut 2kW component hot spots by 10–12°C.

Continuous Fiber Reinforcement: Ceramic-coated carbon fibers create "thermal highways" in ST210G. Maintains insulation while increasing through-plane conductivity to ~0.6 W/m·K—ideal for 3kW industrial converters.

Electronics (wearable medical devices, mini EV BMS) need smaller PCBs. ST210G adapts:

Thin-Core Variants: 0.4–0.6mm thin-core ST210G retains 90% thermal performance of 1.6mm versions. Suits mini BMS in electric scooters, cutting PCB size by 40%.

Embedded Heat Sinks: Integrate thin copper heat sinks into ST210G layers during lamination. Eliminates external heat sinks, reducing PCB height by 50% for wearable devices.

Sustainability is a priority—ST210G evolves to reduce environmental impact:

Recycled Fillers: 30% recycled aluminum nitride (from end-of-life ceramics) in ST210G cuts carbon footprint by 25% without performance loss.

Bio-Based Epoxy: Plant-derived epoxy (castor oil) replaces petroleum-based resin. Retains thermal stability and conductivity, adding biodegradability at end-of-life.

Recyclable Structure: ST210G’s layers (glass fibers, copper, resin) are optimized for disassembly. Recyclers separate materials, reducing e-waste from obsolete PCBs.

IoT and AI enable proactive heat control—ST210G integrates with these technologies:

Embedded Sensors: Thin-film temperature sensors embedded in ST210G layers monitor hot spots in real time. Data feeds to AI systems, adjusting cooling (e.g., fan speed) to prevent overheating.

Thermal Predictive Analytics: AI models use ST210G’s thermal data to predict heat-related failures. A solar inverter maker used this to schedule maintenance, reducing unplanned downtime by 35%.

ST210G CEM3 Thermal Performance redefines how high-power electronics manage heat—balancing conductivity, stability, and cost to solve standard CEM3’s limitations. Its core traits—enhanced thermal transfer, resistance to high temperatures/shock, and compatibility with cooling solutions—make it indispensable for industrial power supplies, automotive BMS, and portable tools.

Real-world applications prove its impact: lower hot spot temperatures, longer component lifespans, and reduced warranty costs. PCB design optimizations—thermal vias, copper planes, cooling integration—unlock its full potential, ensuring designs meet strict reliability standards.

As electronics miniaturize and electrify, ST210G evolves: higher conductivity for ultra-high-power systems, smaller form factors for compact devices, and sustainable formulations aligning with ESG goals. For engineers building durable, efficient high-power electronics, ST210G is not just a substrate—it is a strategic enabler of next-generation designs.

In a market where heat management determines product success, ST210G CEM3 stands as a critical solution, bridging the gap between performance, cost, and reliability for mid-tier high-power electronics.

Related Articles

CEM3 PCB Manufacturer for Cost-Effective Industrial Electronics

CEM3-09HT Thermal Conductive PCB: Dual Advantages of High-Temp Resilience and Heat Dissipation

Countersink Holes in CEM3 PCB: Ensuring Structural Integrity and Assembly Precision

KB7150T High TG CEM3 Circuit Board: Reliable Performance for High-Temperature Electronics

HA30 CEM3 Thermal Conductivity Specs: Guiding Heat Management in Mid-Tier Electronics

LED Light CEM3 Circuit Board: Key Attributes and Applications in Modern Lighting Systems

Low CTE CEM3 Material for High Stability: Ensuring Precision in Dynamic Operational Environments

Thermal CEM3: Balancing Heat Management and Practicality in Electronics Substrates

Got project ready to assembly? Contact us: info@apollopcb.com

We're not around but we still want to hear from you! Leave us a note:

Leave Message to APOLLOPCB